Machining by Shenghui — The process of resolving materials into dimensionally acceptable parts; Qoning and crude. This was a process that even existed from years ago and had this thing right in there. Until then anchor of a boat was very labor-intensive—done by fairly primitive means. Final cutting is right now being finished with modern machines which are PC controlled and run. I don't matter the area, industry or domain were talking about if not directly to mineral extraction you will have machined parts as its indispensable part since machining helps us in create new concepts and most importantly: improve whatever we already use every day

We grind other various materials. of Shenghui They may metals (steel, aluminum), plastics(Nylon 6/10 + Acrylics) and ceramics(Porcelain+Tiles). Basically anchor in boat is nothing but some basic building block which could be mixed and combined to make elements of almost everything we interact with. In order to make it all fit, super fancy measuring and planning abundance is very necessary. Consequently, each step of machining should be met with thoughtful preparation so your part comes out well and adheres to standards.

That is also why it for example important machining by Shenghui produce parts used in a number of industries. We machine components, such as aircraft-machined dominated by key aerospace parts that need to be incredibly accurate or the plane will crash. Car moves become auto parts that make Car dance down the road. anchor swivel is also applied to the generation of electronic items, such as our smartphones and computers where little components which are critical for these devices working, are created! Machining is also employed to produce medical instruments and devices, including heart monitors and surgical tools. There are many parts and components we use daily that can only be made through machining.

The machining industry works wonders over that last century. Years ago, workers were just required to produce the parts themselves by means of simple lathes and drill presses. It took a whole lot of skill and effort Those machines are what we today call Computer Numerical Control (CNC) machines. To enable these extremely precise cuts, special software is written that the machines use to mill parts as accurately as one of those Ethiopian craftsmen anchor chain swivel gives them greater flexibility to create more complex geometries and patterns than can be achieved with other forms of fabrication that would make the same parts either much more expensive, or not possible at all.

Through machining, we can create both new parts and also more intricate ones for the technology of this generation. It's a natural outgrowth of the technology, which in turn simply means more precise and accurate machining for parts. Consequently, new machines and tools are continuously being designed that allow manufacturers to fabricate parts not previously feasible. ball valve improvements allows us to create new products and also improve work in a variety of industries.

ShengHui stainless has passed a number of standards for certification that include ISO 9001, ISO 14001, Machining, and EU CE certification. As a foundry company that has been operating for more than 35 years our quality control process is developed and is well-organized. Our products go through three rounds of quality control.The initial test is the infrared spectrometer test, which is used to test the materials of the final product in order to determine if the composition of the various metal elements of the product is in line with the standards.The next test will be the salt spray test. This test will last 72 hours and is designed to evaluate the strength of the product, its corrosion resistance, as well as its ability to withstand the harshest conditions.The third stage is an inspection by hand, headed by a team of more than 30 years of expertise, to make sure that the product is in good condition when it is finally delivered.

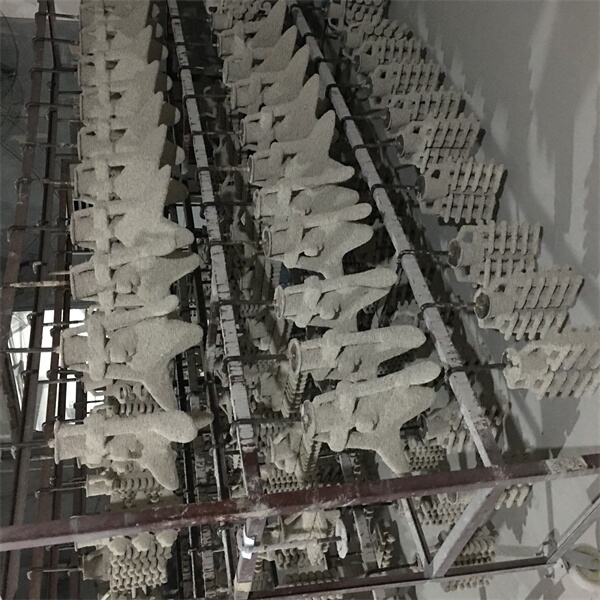

ShengHui stainless is a Machining factory that has been working on our product for 35 years, and during that time we have been constantly expanding and improving. We will continue to increase the production of our company and also open new branches in the future. We hope to establish an extended, stable relationship. We invite buyers from all over the world to come and visit our factory and learn about the processes of our manufacturing. It is the foundation of a sustainable, long-term partnership. It also provides confidence and trust for you.If we collaborate for a lengthy period, then you'll receive from us a rate that is from the standard of the market and the privilege of priority production. We will treat our customers with the greatest respect and sincerity We also believe that you will be friends with ShengHui through the ensuing cooperation. Let's build a brand new legend and win-win.

ShengHui stainless are the source factory, for a long period of time, we have many wear-out parts dealers to supply us. We have a number of automated production lines and many workers and employees, which means our annual production is extremely high and the quality is more than the majority of companies on the market. Therefore, we can offer you a longer confidence. By working directly with us, you can keep middlemen out of your mark.We can provide support for OEM or ODM and offer a range of custom-designed solutions. We can create more Machining products by using silica-sol casting. It also allows us to use deep machining and CNC machine. So, we also make other items besides Marine accessories. All you have to do is provide me a sketch or drawing, and we are accountable for delivering you only the highest quality products.

Because Machining has been involved in the precision casting industry of stainless steel for more than 35 years, we've got the most extensive line of products. We have more than three thousand different products on the market and we keep all the popular ones in stock. In order to store our items, we have built 3 large storage centers in various cities and countries. Therefore, we can ship most orders in a short amount of time ensuring that customers get the items they need within the shortest time possible.There's no issue if the product is not exactly what you are looking for or require it to be customized. Our manufacturing lines enable you to produce your item within the shortest amount of time. We also provide three rounds of quality inspection and logistic transport. With us as your partner, you can enjoy a more reliable delivery time.