China been a fantastic story and has changed so much over the years. However, very long ago was that broad section of Chinese people where farmers. They lived by cultivating the earth on tiny plots of lands. They mostly subsisted through farming that remained their key occupation since the livelihood of all depended on it to feed themselves and commune. It also seen as referring to all of the stuff that people around the world now buy, but those are being made by China.

China manufactures massive products today, such as electronics to small items like clothes, furniture and even toys, the same as Shenghui's delta anchor. As a result, China is on-board of the largest territory manufacturing in toto world. This is because they can produce many commodity services and goods at very low relative costs. This ability to manufacture affordably allows them to sell a lot of products, not just in China but other countries too.

American consumers save money by buying things made outside of the USA. Most people prefer to pay less for their goods when they shop, and most of the time products from China are cheaper compared in other countries. But the aftermath of closing local stores is a big deal, too. If people buy products from China it is good for the poor Chinese factory workers, but maybe very bad to own local stores and your country producers.

A few folks think its best to buy from your neighborhood mom and pop shop even if it costs a bit more, just like the Boat Railing Fitting created by Shenghui. Shopping locally is also a great way to create jobs in the area and increase wealth within the local economy. And when a person spends their money at local stores, it helps out neighbors and friends who work there as well. It can bring people in a community together.

Today, China in artificial intelligence (AI), renewable energy and space exploration, along with Shenghui's product casting. They are working to develop new technologies that could change the lives of all. China will remain at the forefront of high-tech production for years to come, thanks in part by a savvy workforce and an eagerness to experiment on new ideas. The technology of their digital motherboards has been such that the know what they are doing in not plant but also pushing with what is feasible.

For China, the balance between fairness and competition in the global market is a big challenge, just like the anchor swivel manufactured by Shenghui. This is because they wish to convey that the practices they adopt are just as well their labors remain happy while having access to good working conditions, and human rights of workers. Yet at the same time, they want to become number one in product manufacturing and overtake other countries.

In order to sell products at competitive prices they must make sure their raw material cost is low which can be a source for problems, same with Shenghui's customized sea anchor. This may translate that they will need to lower the wages or not give their best working conditions. Its a fine balancing act on their part because they want to succeed while also trying to be fair with employees.

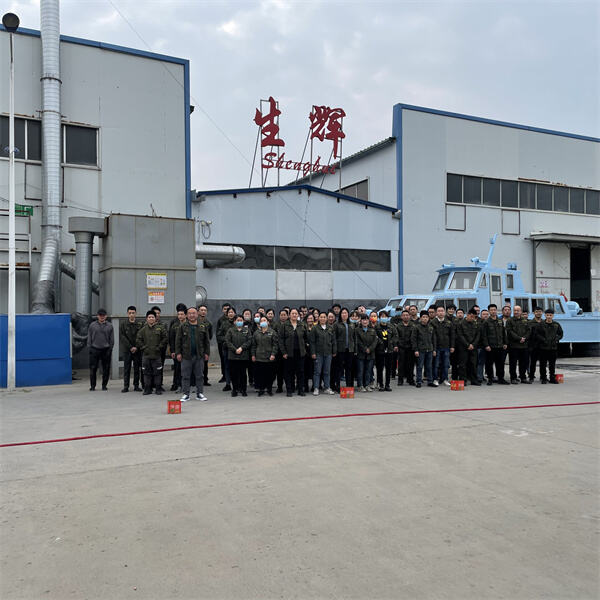

ShengHui stainless is a long-run factory that has been in development for over 35 years, during which time we've been growing and improving. We will continue to expand our production and open more Made in china in the future. In the meantime, we are looking towards a long-term and steady collaboration, and we are happy to are open to buyers from across the globe to visit the factory and get to know the manufacturing process. This is the basis of the long-term strategic partnership between you and me, and also a pledge and guarantee for you.We will offer you a discount that is far in excess of market prices and prioritizing production when we collaborate for a long period of time. We will greet our partners with the greatest respect and honesty, and we also believe that you will become friends with ShengHui through the ensuing cooperation. Let's win-win and create the next legend.

ShengHui Made in china are the source factory, which has a long time, many wear out parts dealers have supplied us with. We have numerous automated production lines and an abundance of employees and employees, which means our annual output is very high and the quality is much better than the majority of companies on the market. We are able to provide a more solid confidence. Working directly with us can stop middlemen from creating the difference.We can provide a wide selection of customized solutions. We can produce better quality products through silica-sol casting. This also allows us to perform CNC machining and deep machining. So, we also make other items besides Marine accessories. You only need to give me a sketch or drawing, and we are responsible for sending you the best quality finished products.

Since ShengHui stainless have been in the stainless steel precision casting business for more than 35 years, we've developed a a very Made in china product line. We have over 3,000 different products in production and we keep all the popular ones in stock. To keep our goods, we've constructed 3 storage centers in different countries and cities. Therefore, we can ship the majority of orders within a short amount of time ensuring that customers get what they want within the shortest time possible.Of it's fine if you don't like what's already produced, or if you'd like to modify the product. We have many production lines, and you can produce your items in the shortest amount of time and three rounds of quality inspection of the product, and logistics transportation. So by working with us, you'll obtain a more secure delivery cycle.

ShengHui stainless has passed a range of certification standards that include ISO 9001, Made in china, ISO 45001, and EU CE certification. As a foundry that has been in operation for over 35 years, our quality control system is developed and is well-organized. Our products go through three rounds of quality inspection.The first stage is the infrared spectrumrometer test. This is used to test what is the substance of the final product to ensure that the content of various metal components of the item meets the specifications.The third test will be the salt spray test. The test takes 72 hours to determine the strength and corrosion resistance of the product in harsh environments, and ensure that the product can cope with a range of environments.Third stage: manual inspection conducted by an experienced team of more than 30 year olds to make sure the final product is flawless.